Learn More About...

We include everything essential for you to create your new cabin structure. The entire kit is neatly packaged on a pallet system that can be shipped anywhere. Everything in the kit is already precision milled to fit together perfectly with minimal fasteners and features our premium double tongue and groove InterStack Log™ wall system with integrated CrossLock Corners™ All of the main parts are also individually ID numbered so it’s easy for you to understand where everything goes when you assemble it.

You can purchase this kit as a DIY project and assemble it yourself. All you will need to provide is a level foundation base and your choice of roof covering material.

You can also choose to purchase this kit with an “Assembly Package” add on and we will come to your property and do it all for you in as little as one day. Our assembly package includes Delivery + Assembly + metal roof covering panels.

*Assembly packages are subject to site inspection for price confirmation and require an approved client supplied foundation base.

Read below to learn even more details about each model plus you can download useful manuals, spec sheets and foundation base plans.

Heating and air conditioning

We are often asked about heating and air conditioning options for our cabins. You can heat or cool your cabin structure at your discretion.

There are many options you could consider such as electric heaters, wood stoves, propane furnaces, heat pumps and various other cooling solutions such as portable and or permanent air conditioning units.

Choose the method which suits your needs and be sure to always follow and align to safety regulations and seek the help of a heating and cooling professional when attempting any installation or option.

Foundation

Setting up a foundation base is the first step in starting your project. It is important your structure rests on a level well-built foundation. Choose a location that has good drainage and allows for adequate clearance around the perimeter for assembly.

Your structure can sit on uneven ground as long as you take the necessary steps to level the foundation via footings and posts. There are many types of foundations you may elect to use. You may choose to build our structures on an adequate existing or new level platform such as a deck, patio, driveway, concrete slab or pressure treated timbers on grade.

Our suggestion is for you to construct a very simple wooden pressure treated deck frame supported by footings that best suit your building sites grade and soil conditions.

You may choose to explore various foundation footings types such as professionally installed screw piles, or these impressive DIY screw piles available at www.fastfootings.com or poured concrete sono tubes or suitable on-grade concrete block footings or pads.

We have provided you with a complete detailed building plan to create the wooden deck base foundation for this model. See the “How to assemble resources” section for the foundation base plan download.

Insulation

We are often asked if our structures are insulated. Many of our clients are very happy using our structures with no insulation at all. A decent heat source inside the structure usually is capable to heat up the small space adequately even in colder climates.

The solid wood InterStack Log™ wall system we use to create the main structure of our kits ranges in thickness from 38mm to 90mm thick (depending on the model) The R value of softwood is rated at roughly 1.41 per inch or 1.41 per 2.54 cm However the real hero with solid wooden log structures is the walls thermal mass properties.

When the interior space of your structure is heated the walls act as thermal mass ( think of a large natural thermal battery) Your heat source warms the air and in turn the wood walls absorb and retain a certain amount of that heat and is able to release it back into the structure over time. This is something typical forms of insulation can not do and is unique to solid wood or stone structures. Given the thermal mass properties mentioned we do not feel it is imperative for you to insulate the walls of your structure.

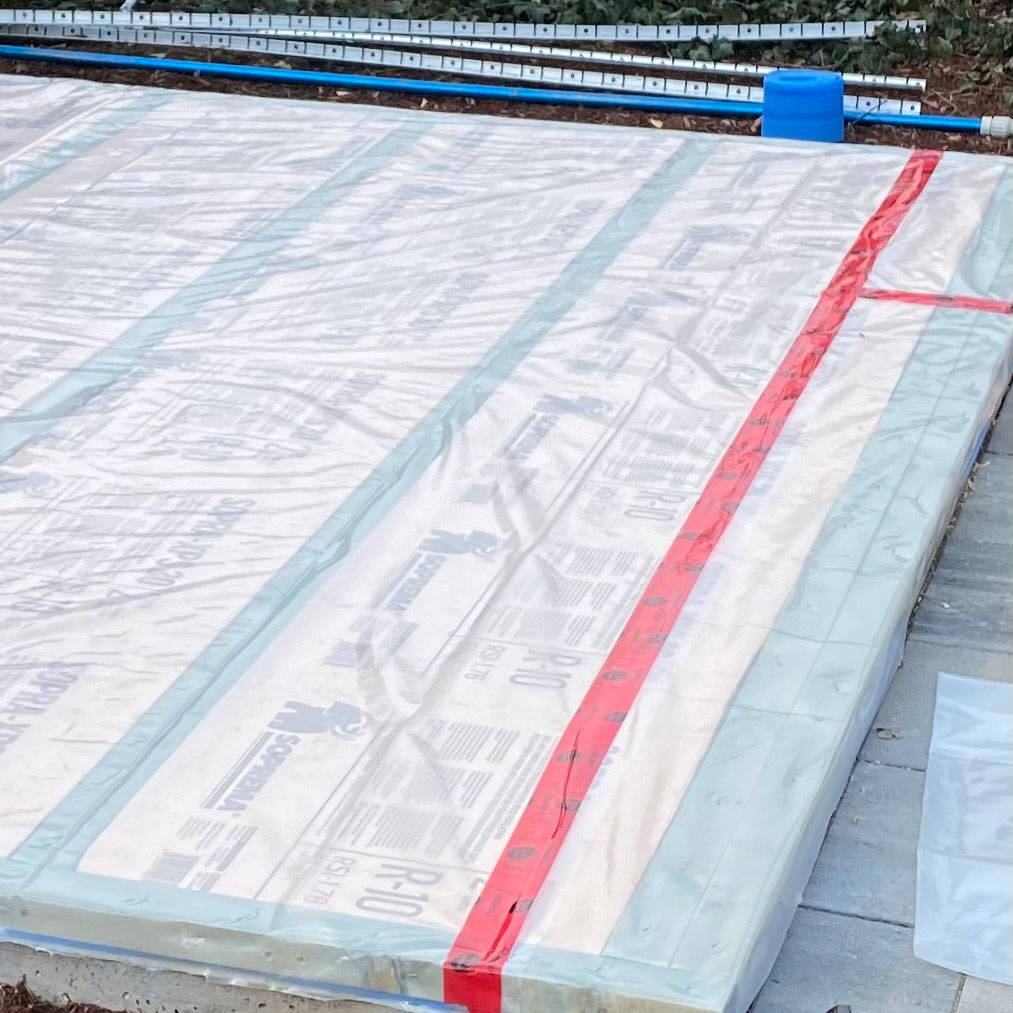

If desired you may elect to insulate the roof of your structure from the outside. This can easily be done by strapping the outside roof with additional lumber and laying in rigid foam insulation panels before you install your chosen roof coverings. This method will help eliminate heat escape in colder climates and reduce the heat intake in warmer climates. This outside insulating method will also allow you to maintain your beautiful interior pine ceiling.

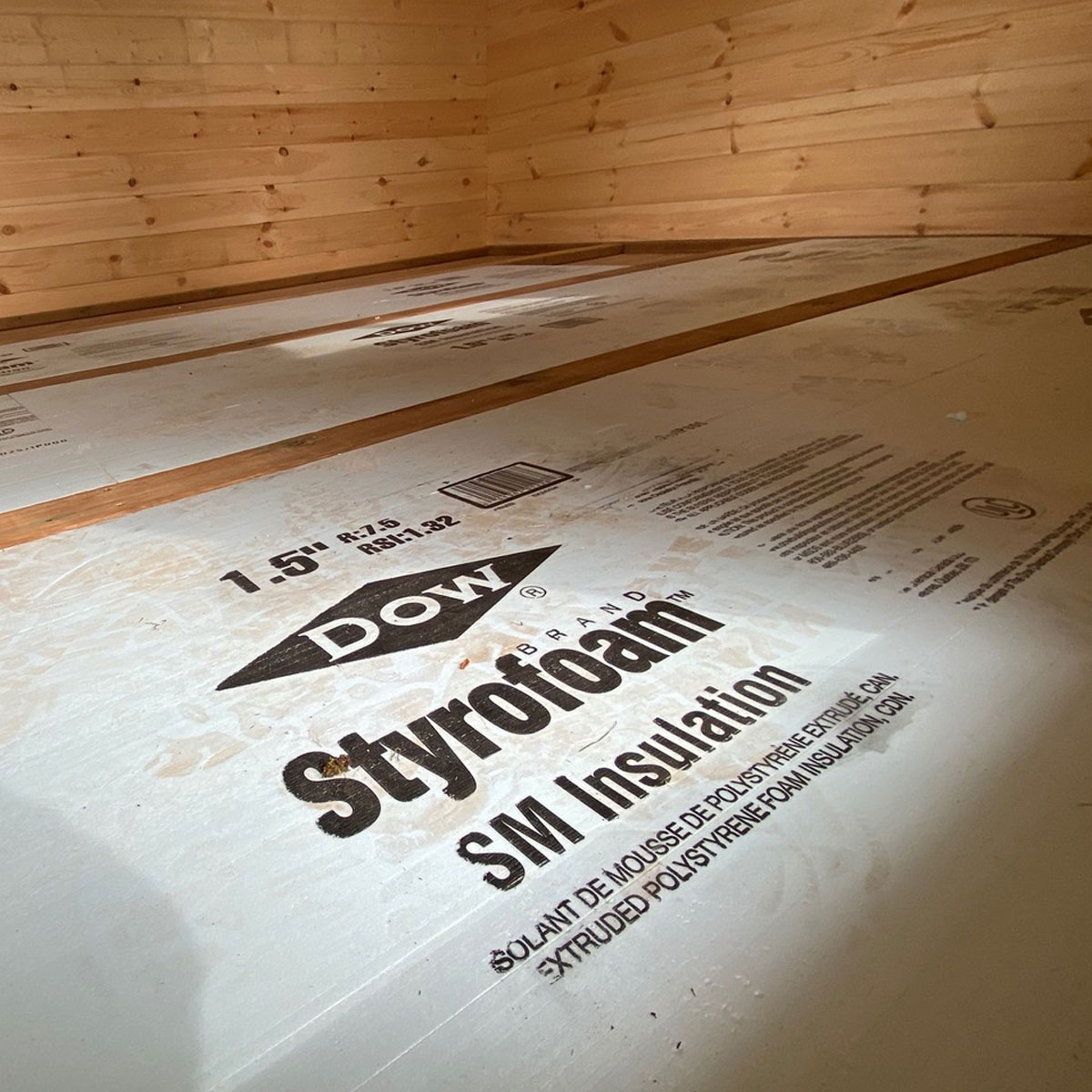

You may choose to also insulate the floor by installing rigid insulation panels into the floor cavity before you apply the floor boards. A quality and appropriate matched heating or cooling source will keep you comfortable in most climates all year long.

Most clients are very happy enjoying their structures with no insulation at all however its your choice to decide what suites your needs

Example of do it yourself rigid foam roof insulation installation

Apply plastic vapor barrier or ice and water shield (optional)

Add strapping in a thickness to fit your desired rigid foam panel

Apply sill gasket under starter strips if applying directly to concrete (not needed on wood frame base)

Position starter strips supplied face down on your foundation base

Insert rigid foam between starter strips

ADDITIONAL FLOOR INSULATION PHOTOS

ROOFING MATERIAL OPTIONS AND INFORMATION

Your kit includes all the essential parts to your roof structure such as roof beams and beautiful tongue and groove ceiling/ roof boards. However we do not include roof covering protection materials such as shingles or steel panels in our DIY kit packages.

All of our assembly packages we do supply and install either a Corrugated Metal Roof or Steel Roof panels depending on the assembly package ordered and model purchased.

Sheet or panel system roofing work best for our cabins as our roof beams (perlins) make for an easy anchor point to install any panel system roof. We don’t encourage shingle roofs as it tend to be more work than needed.

Let’s discuss some of the great panel system roofing options for your new cabin structure

Corrugated Metal (Steel) Roofing

( Typically sold in 36” or 48” widths available in various profiles and colours that can be ordered cut to length )

Corrugated metal roofing material offer several advantages that make it a popular choice for many cabin owners and builders.

Firstly, it is highly durable and very long-lasting, capable of withstanding extreme weather conditions such as heavy rain, snow, and strong winds. Secondly, corrugated metal roofing is fire-resistant, providing an added layer of safety to the structure.

Additionally, it is lightweight, making installation easier and reducing the overall load on the building. corrugated metal is also low-maintenance, requiring minimal upkeep and reducing long-term costs.

Lastly, it is available in a variety of colors and finishes, allowing for greater design flexibility and aesthetic appeal. Overall, corrugated metal roofing material is a reliable and practical option that combines durability, safety, and aesthetics and longevity.

Read even more about Corrugated Metal Roofs. (click through )

Standing Seam Steel Roof

( Hidden fasteners, Interlocking panels typically 12” - 18” widths, can be ordered cut to size or installed by a pro )

Standing seam steel roofing material offers numerous advantages that make it a popular choice among homeowners and architects alike.

Firstly, its interlocking design provides excellent protection against leaks and water damage, making it highly durable and long-lasting. This type of roofing is also highly resistant to extreme weather conditions, such as heavy rain, snow, and high winds. Additionally, standing seam steel roofing is energy-efficient, as it reflects solar heat and reduces cooling costs in warmer climates. It is also low-maintenance, requiring minimal upkeep over its lifespan.

Furthermore, the sleek and modern appearance of standing seam steel roofing enhances the curb appeal of any property.

Overall, standing seam steel roofing is a reliable, energy-efficient, and visually appealing option that offers exceptional durability and protection for both residential and commercial buildings.

We have a solution for a pro to come install a standing seam steel roof on your structure in most regions.

Read even more about Standing Seam Steel Roofs. (click through )

More About Corrugated Metal Roofs

Corrugated metal has been used to cover roofs around the world for decades. Corrugated literally means “shaped into alternating ridges and grooves.” Just as corrugated cardboard can be used to construct some pretty sturdy boxes, corrugated metal also offers some impressive structural strength for many roof applications, thanks to its ridged design.

The corrugated metal is produced by taking a sheet of metal coil and putting it through a roll-forming machine,

which shapes the metal panels into a preset corrugated pattern.

PROS: Corrugated metal continues to be a popular metal roofing method, especially for many commercial, barn, and other non-residential applications. It’s a lower-cost option than some other metal roofing approaches, it’s effective at reflecting away a lot of sunlight and heat, and is more durable and longer-lasting than an asphalt roof.

CONS: One key liability with corrugated metal roofing is the fact that it presents multiple exposed fasteners. While there are treatments available to help protect and preserve these fasteners, inspections are still required every few years to ensure that the washers are still intact, and that the fasteners haven’t loosened.

Another con where corrugated metal is concerned is simply a matter of aesthetics.

While the colors are fairly customizable, the corrugated pattern itself doesn’t carry a reputation of being nearly as eye-appealing as the smoother look of a standing seam finish.

More About Standing Seam Steel Roofs

Like corrugated metal roofs, standing seam roofs are also designed with metal panels that are fabricated by roll forming. The key difference is in the design and application – standing seam roofs take full advantage of having concealed fasteners. A standing seam system consists of wide, relatively flat metal panels that have vertical legs (or ribs) on each end. The metal panels are designed to lock together, and are mounted to the roof by being fastened to the sheathing underneath through a series of hidden clips. All the roof attachments and seams are literally hidden beneath the vertical legs of the standing seam panels.

PROS: When it comes to the pros of a standing seam metal roof, there are many. For starters, the panels are fabricated with a stronger gauge of metal than is used for corrugated metal. No exposed fasteners or seams mean there are essentially no opportunities for leaks to develop, and a standing seam system also requires much less in the way of maintenance.

It’s also highly customizable in terms of colors and profile options, and a standing seam metal roof is even more efficient at reflecting away light and heat. Aesthetically speaking, many homeowners prefer the visual appeal of a standing seam roof with its flat panels and sleek lines. And in terms of longevity, a standing seam roof can easily last you 75 years, or more!

CONS: There really aren’t many. The main caveat with a standing seam roof is its initial cost. A standing seam roof isn’t cheap, and will cost a fair bit more than a corrugated metal roof.

Wood Protection / Staining

It is important to protect the EXTERIOR of your new structure. When shopping for a weather protection stain product there are many choices to consider. We highly recommend the following two products that work remarkably well and provide lasting protection and beauty to any of our wooden exteriors

Sansin:

Sansin stains are a range of high-quality wood stains that are known for their exceptional performance and environmentally friendly formulation. Sansin offers a variety of stains and finishes designed to protect and enhance the natural beauty of wood surfaces, including wood siding, decks, siding, fences, and furniture.

Sansin stains are formulated with advanced water-borne and oil-based technologies, allowing them to deeply penetrate the wood and provide long-lasting protection against UV rays, moisture, mildew, and other environmental factors. This helps to prevent the wood from cracking, warping, or deteriorating over time.

Sansin provides a wide range of color options to suit different preferences and design styles. Whether you prefer a transparent or opaque finish, Sansin offers a variety of options to achieve the desired look.

Learn more about Sansin: https://www.sansin.com/

Select a colour for your cabin here: https://www.sansin.com/color/

Find a dealer near you: https://www.sansin.com/dealer-locator/

Cutek Extreme: is a super penetrating oil product meant only for exteriors. It is very easy to apply with a brush and only takes on average of a few hours to complete an exterior. Cutek offers super protection from the elements while providing a beautiful luster to our wood. Tints are available or you can choose the natural tone as shown in the photos and video.

www.cutekstain.com– available at Home Hardware and many other select retailer.

Utilities

Plumbing: We do not offer plumbing services, however all of our structures can easily accommodate your plumbing needs via installation through any local licensed plumber.

Electrical: We do not offer electrical services, however our structures can easily accommodate any of your electrical needs such as outlets and lighting. Your best solution to install wiring and electrical in our solid log wall structure is by way of pipe style conduit or baseboard boxes. These solutions can easily be provided and installed through any local licensed electrician.